Interesting problems – convincing solutions

Problems due to high reactive currents

The company ESD-Sic b.v. in the Netherlands is one of the leading manufacturers of silicon carbide. During the production process, a mixture of pure quartz sand and petroleum coke is heated under a plastic tarpaulin (Picture 1) to a temperature of approximately 2300° C by supplying electric energy with a rated voltage of 500 - 600 V, 50 Hz. Both source materials react to silicon carbide. The reactive power load of the process is 7000 - 8000 kVAr.

Picture 2 shows the exposed silicon carbide roller which has grown after some days around the U-shaped graphite core.

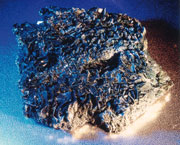

Picture 3 + 4 shows the silicon carbide crystals extracted from the solidified melt.

The SYSTEM ELECTRIC solution

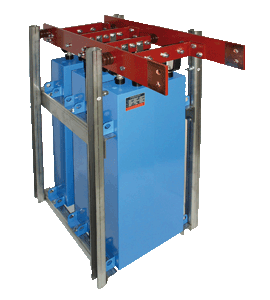

Picture 5 shows a 700 kVAr oven capacitor bank from SYSTEM ELECTRIC. Ten of these units are necessary per process line to keep the energy and production costs within reasonable limits. The capacitors are self-healing and environment-friendly.

Capacitive electrical network load

- specific cos φ reduction

.

The problem

In Wilmersdorf, Germany, a solar park of Sun Concept GmbH is planned to go on line with a power of P = 1,000 kW peak. The system’s cos φ is ideal – close to 1. Based on the electrical network conditions (mainly cable systems and other solar supply systems), the local power supply company requests a cos φ (at the transfer point) of ≤ 0.95 inductive. The aim was a range of 0.93 – 0.95 for the cos φ.

The SYSTEM ELECTRIC solution

An automatically controlled inductive power factor correction system of 325 kVAr, 400 V / 50 Hz. The integrated 9 inductances (reactors) are arranged in a control series of 1:1:2:2:4:4:4:4:4 in 26 steps of 12.5 kVAr each, as required, so that the cos φ is reliably kept in the range 0.93 – 0.95.